Maximize

Maximize - Remove this product from my favorite's list.

- Add this product to my list of favorites.

- Send to a friend

ShopsmithUK Facebook link

I hope you take the time to visit my Facebook page for ShopsmithUK

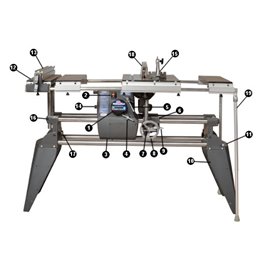

On it you will find all the promotional videos of the latest Power Pro Mark 7 in action

The link will take you off this site to other servers over which I have no control.

If you wish to register on any of these sites be aware you will need to setup your own login information.

Please do not use the same login details as your one for the Martins Supplies Sales site.